|

|

|

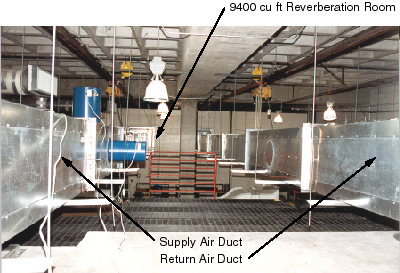

The test facility at CMEST

for the airflow performance and sound testing of duct elements has two

fan rooms that are adjacent to each other. The fan rooms are on a

mezzine level approximately 90 ft from the front of the 9400 cu ft

reverberation room. One room contains the supply air fan and the other

contains the return air fan. The fans can be operated independently or

in parallel. Air can be drawn in from the outside and discharged to the

outside. For this configuration the dampers between the two fan rooms

are closed and the inlet and discharge air dampers to the outside are

open. Air can also be directed in a closed loop between the

reverberation room and the two fan rooms. For this configuration the

inlet and discharge air dampers to the outside are closed and the

dampers between the two fan rooms are open. Between the fans and the

ducts that connect the fan rooms to the reverberation room are a sound

plenum, a ten-foot silencer bank, and another sound plenum. The length

of the ducts between the second sound plenum and the reverberation room

is 90 feet. The maximum size of the ducts that can be placed between the

fan rooms and the reverberation room is 5 ft by 5 ft or 5 ft diameter.

The picture below is a picture of the supply and return air ducts that

are placed between the fan rooms and the reverberation room. The duct on

the left is the supply air duct and the duct on the right is the return

air duct.

The fans in the two fan rooms are six-foot diameter

Joy vane axial fans. Figure 8 shows the inlet section of the return air

fan. The fans are variable-speed, adjustable-pitch fans. Each fan is

controlled by a 65 horsepower, variable-frequency inverter. The pitch of

the fan blades of each fan can be adjusted after the fan has come to a

complete stop. Using the adjustable pitch capability of each fan along

with its variable-frequency inverter, the flow capacity of each fan can

be varied from 1,000 cfm to around 60,000 cfm at a total static pressure

of 4 inches H20. As was mentioned above, the fans can be

operated individually, or they can be operated together with each fan

running at the same rpm.

A rail with a movable one-ton hoist is located above

the entire length of each duct between the fan rooms and the large

reverberation room. The ducts are usually installed in ten-foot

sections. Thus, it is possible to change out complete or partial duct

runs with a reasonable amount of effort.

The current configuration of ducts is set up to

conduct ASTM E477 tests on duct silencers. The sections of duct between

the fan room and the test section are constructed of dual-wall ducts

with a cavity depth of 4.25 inches. The inside dimensions of the ducts

are 24 in by 24 in. The inside and outside walls of the ducts are

constructed of 18 gauge sheet metal and the cavity is filled with

fiberglass. The sections of duct between the test section and the

reverberation room are constructed of dual-wall ducts with a cavity

depth of 2.25 inches. The inside and outside walls of the ducts are

constructed of 18 gauge sheet metal and the cavity is filled with

fiberglass. Silencers with lengths of up to 10 ft can be tested. There

are test sections in both the supply air and the return air ducts.

The sound source for the ASTM E477 test consist of

three speaker canisters that are mounted directly to the duct walls of

either the supply or return air duct. One canister contains a 500 watt

18-inch diameter low-frequency speaker; the second canister contains a

500 watt 8-inch diameter mid-range speaker; and the third canister

contains two 50 watt high-frequency tweeters. The power source consists

of a single-channel equalizer, a three- to five-way adjustable crossover

network, a 1,000 watt stereo amplifier (500 watts per channel), and a

100 watt monaural amplifier. Pink noise is directed into the equalizer.

The crossover network is adjusted with crossovers at 300 Hz and 3,000

Hz. Sound energy at frequencies less than 300 Hz is directed through one

channel of the stereo amplifier to the low frequency speaker. Sound

energy at frequencies between 300 Hz and 3,000 Hz is directed through

the other channel of the stereo amplifier to the mid-range speaker.

Sound energy above 3,000 Hz is directed through the monaural amplifier

to the high-frequency tweeters.

Two piezometric rings, one placed ten feet upstream of the test

section and the other placed ten feet downstream of the test section,

are used to measure the static pressure drop across a duct silencer or

other duct element that is being tested. A Pitot tube rake (five

individual Pitot tubes connected to a single manifold), along with the

upstream piezometric ring, is used to measure the velocity pressure and,

consequently, the flow velocity and flow volume of the air flowing in

the duct during a test. The static pressure drop and the velocity

pressure are continuously monitored by means of differential pressure

transducers that are connected to digital meters. Piezometric rings and

Pitot tube rakes are located in both the supply air and the return air

ducts.

Students setting up for airflow

friction loss tests of a

rectangular duct that is internally lined with fiberglass. |

|

|